Producing hydrogen from water, sunlight and some catalyst-coated chips of silicon – we are getting closer to doable home electricity for the technically challenged…

‘Artificial leaf’ gains the ability to self-heal damage and produce energy from dirty water

Another innovative feature has been added to the world’s first practical “artificial leaf,” making the device even more suitable for providing people in developing countries and remote areas with electricity, scientists reported here today. It gives the leaf the ability to self-heal damage that occurs during production of energy.

Daniel G. Nocera, Ph.D., described the advance during the “Kavli Foundation Innovations in Chemistry Lecture” at the 245th National Meeting & Exposition of the American Chemical Society.

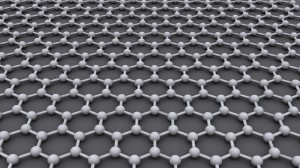

Nocera, leader of the research team, explained that the “leaf” mimics the ability of real leaves to produce energy from sunlight and water. The device, however, actually is a simple catalyst-coated wafer of silicon, rather than a complicated reproduction of the photosynthesis mechanism in real leaves. Dropped into a jar of water and exposed to sunlight, catalysts in the device break water down into its components, hydrogen and oxygen. Those gases bubble up and can be collected and used as fuel to produce electricity in fuel cells.

“Surprisingly, some of the catalysts we’ve developed for use in the artificial leaf device actually heal themselves,” Nocera said. “They are a kind of ‘living catalyst.’ This is an important innovation that eases one of the concerns about initial use of the leaf in developing countries and other remote areas.”

Nocera, who is the Patterson Rockwood Professor of Energy at Harvard University, explained that the artificial leaf likely would find its first uses in providing “personalized” electricity to individual homes in areas that lack traditional electric power generating stations and electric transmission lines. Less than one quart of drinking water, for instance, would be enough to provide about 100 watts of electricity 24 hours a day. Earlier versions of the leaf required pure water, because bacteria eventually formed biofilms on the leaf’s surface, shutting down production.

“Self-healing enables the artificial leaf to run on the impure, bacteria-contaminated water found in nature,” Nocera said. “We figured out a way to tweak the conditions so that part of the catalyst falls apart, denying bacteria the smooth surface needed to form a biofilm. Then the catalyst can heal and re-assemble.” …

via ‘Artificial leaf’ gains the ability to self-heal damage and produce energy from dirty water.